Tungsten copper composite material is a unique bimetallic composite material composed of immiscible tungsten and copper. It is widely used in high-voltage electrical contacts, electrical machining electrodes, electronic packaging, nuclear fusion, electromagnetic propulsion, and other fields. The development of science and technology and the expansion of new application fields, place higher requirements on the comprehensive performance of tungsten copper composite materials. However, there is still a lack of effective methods and means to make tungsten copper composite materials have high strength, high plasticity, and high conductivity.

In this regard, Professor Song Xiaoyan’s team at Beijing University of Technology proposed an innovative cross-scale multi-level design concept for tungsten copper composite materials. Using SPS Spark Plasma Sintering Technology successfully prepared the self-assembled layered tungsten copper composite materials (SAL W-Cu). Deeply analyze its microstructure, mechanical properties, strengthening and toughening mechanism, and conduction mechanism. The relevant results have just been published in the international authoritative journal Nature Communications. Associate Professor Han Tielong of Beijing University of Technology is the first author and co-corresponding author of this article.

Full-text link: https://www.nature.com/articles/s41467-024-46029-w

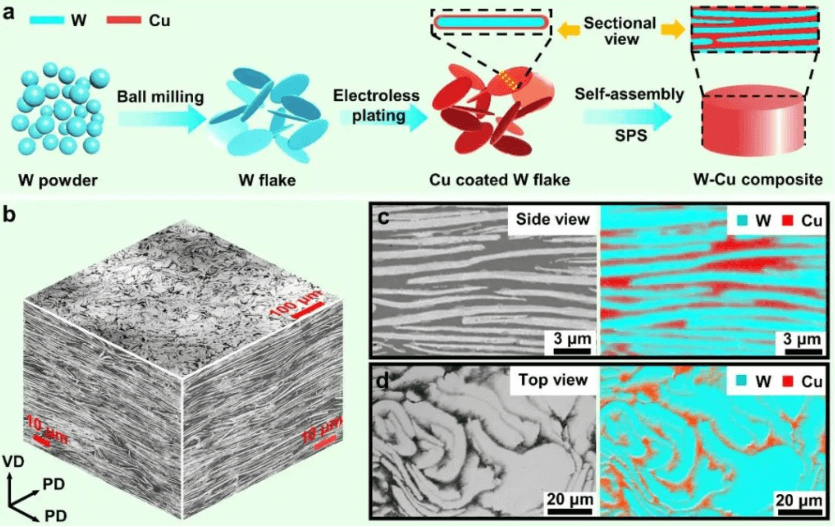

The paper first proposed the design concept of a multi-level layered self-organized structure. In the experiment, the author first prepared ultrafine tungsten flakes with high-density dislocation structures by pretreatment. Then by adopting chemical plating uniformly deposited a layer of nano-copper on its surface to prepare a lamellar tungsten-copper composite powder. Load the composite powder into a carbon-carbon composite mold with a diameter of 20mm after hydrogen reduction. Finally, sinter it in our SPS Spark Plasma Sintering Furnace to prepare a multi-level layered tungsten-copper composite material. The sintering temperature used was 960℃, the pressure was 125MPa, and the insulation time was 10min.

Experimental results

The comprehensive performance of the tungsten-copper composite material is also significantly improved compared with the tungsten-copper composite materials prepared by other processes.

Due to the self-organized layered structure, tungsten-copper composite (SAL W-Cu) has significant anisotropy. Therefore, divide the compression performance testing into parallel to the lamellar direction (PD) and perpendicular to the lamellar direction (VD) tests. The compressive yield strength of PD reached 1130MPa, and the compressive yield strength of VD was 1040MPa. This data is almost twice the yield strength of commercial coarse-grained tungsten copper composite materials (~600MPa). In addition, SAL W-Cu has obvious strain-hardening behavior and high damage tolerance, and fracture deformation can reach 14%. This can effectively avoid accidents caused by sudden failure and is conducive to safe design in engineering. More importantly, SAL W-Cu has excellent mechanical properties while maintaining an electrical conductivity of 56%IACS. And a thermal conductivity of up to 242W/K m. This makes its application prospects broader.

This study provides a new design idea and implementation technology for obtaining bimetallic composite materials with excellent comprehensive properties such as high mechanical properties and physical properties. It provides an important reference for solving the problem of preparing high-quality tungsten copper composite materials.