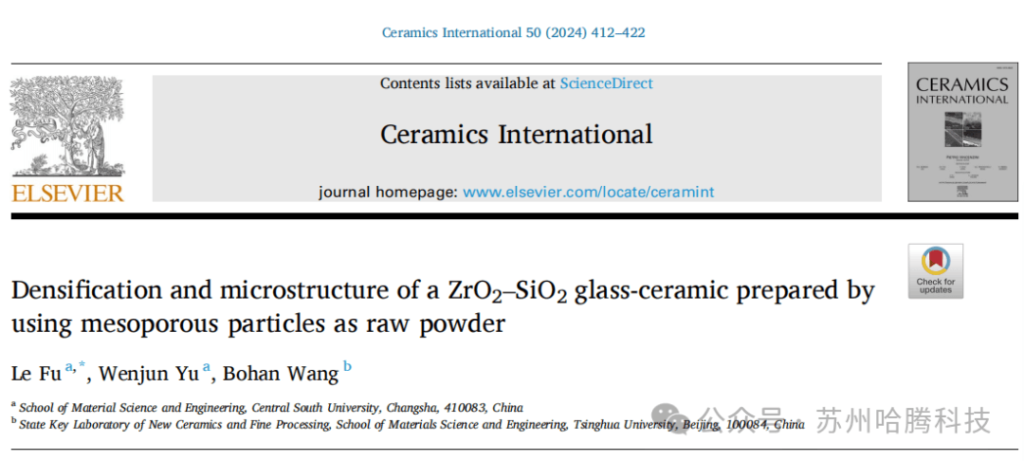

Ceramic sintering is an energy-intensive industrial process. If we can lower the sintering temperature and shorten the holding time, that can effectively reduce carbon emissions. This is of great significance to environmental protection. It has been reported that using mesoporous powder as raw material can achieve this.

Professor Fu Le and collaborators from Central South University took the ZrO2-SiO2 composite glass-ceramic system as the research object and designed and produced mesoporous powder raw materials. Then use SPS Spark Plasma Sintering Technology to explore the sintering densification behavior and compare it with ordinary powder raw materials. The relevant results were published in “Ceramics International”.

Experiment Process

Prepare ZrO2-SiO2 mesoporous powder by micelle-assisted coprecipitation method. After vacuum filtration and drying, calcine it at 600℃×1h to obtain a mesoporous powder raw material with good morphology. Ordinary powder raw materials without mesoporous structure were prepared by traditional methods for comparison.

The sintering experiment was carried out in our CNE-FHP-858 SPS Spark Plasma Sintering Furnace.

Use the Mesoporous powder and ordinary powder as raw materials. Load them into graphite molds with an inner diameter of 12 mm, and pre-pressed to 15 MPa. Then the temperature was raised to 800 ° C and kept for 2 minutes. During this period, the pressure gradually increased to 50 MPa. Next, raise the temperature to 1100 ° C at a rate of 100 ° C / min. Then the temperature was raised to 1230 ° C at a rate of 50 ° C / min, and the temperature was lowered with the furnace after 4 minutes of keeping, and the sample was de-molded.

At the same time, the corresponding comparative samples were prepared by conventional pressureless sintering.

Experiment Result

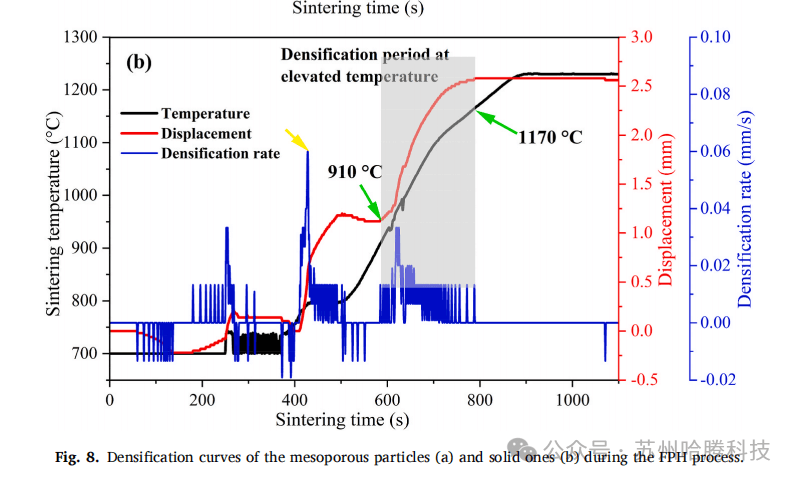

CNE-FHP-858 SPS Spark Plasma Sintering Furnace records the temperature, pressure, and displacement curves during the sintering process in real-time. It is helpful to analyze the densification process of the sample. We can see from the figure, that the temperature control of the sample is very precise, with basically no overshoot. The temperature fluctuation during the constant temperature process is within ± 1℃. The displacement curve faithfully reflects the densification process.

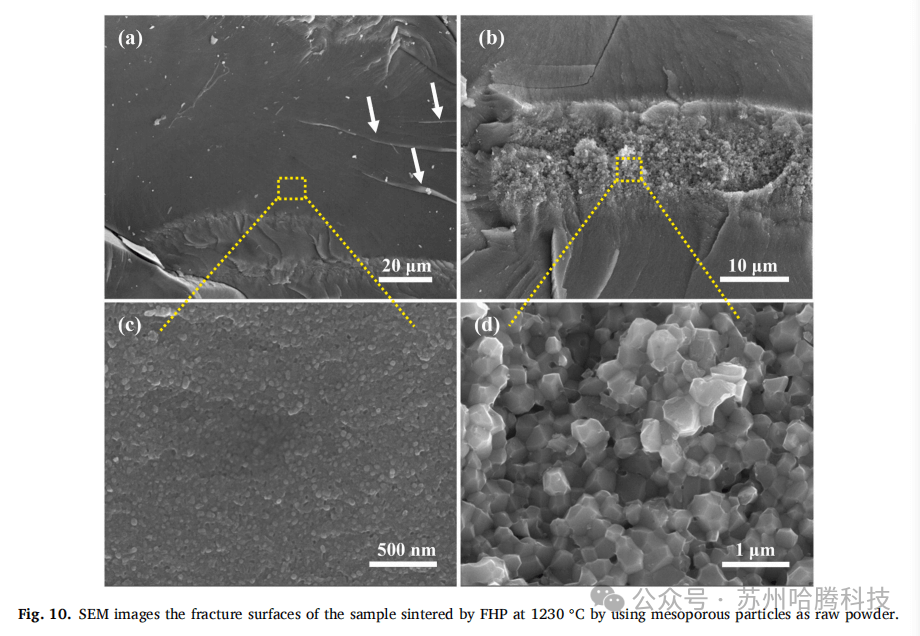

During the sintering process, ZrO2 nanocrystals crystallize in the mesoporous particles and embed into the SiO2 matrix to form a two-phase microstructure. ZrO2 crystallites and grain boundaries are formed in single-phase amorphous ZrO2 particles, forming a single-phase microstructure. In general, the sintered samples show an inhomogeneous microstructure.

By comparing the sintering densification behavior of mesoporous powders and ordinary powders, it was found that the mesoporous structure did not significantly reduce the sintering temperature.

The study also showed that the SPS Spark Plasma Sintering Furnace can record the densification process in real time. This provides a useful technical route for studying the sintering mechanism of ceramics.