High entropy alloy is one of the star materials booming in recent years. Its composition is complex, and to quickly obtain an optimized formula and preparation process. It requires a very large amount of sample preparation work. SPS sintering has become a powerful tool for high entropy alloy research with its high efficiency and low cost.

Recently, Professor Chen Hongsheng’s research group at the Taiyuan University of Technology published a research paper entitled “Interfacial bonding behavior of WC/AlCoCrFeNi2.1 eutectic high-entropy alloy matrix composites fabricated by fast hot pressing sintering” in the journal “Vacuum”. It discussed the effect of WC reinforcement on the mechanical properties of dual-phase five-element high entropy alloys. Our SPS spark plasma sintering furnace mainly completed the sample preparation.

Experiment Process

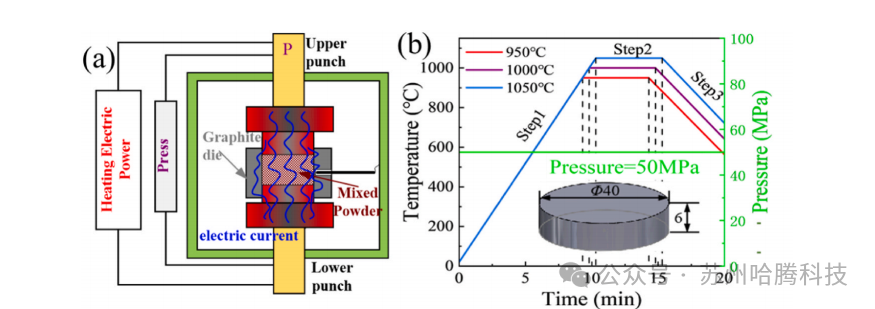

In this experiment, high entropy alloy powder and tungsten carbide powder are spherical powders. Then they were ball-milled and mixed in a planetary ball mill according to the proportion designed in the experiment. Then the powder was loaded into a graphite mold with an inner diameter of 40mm, and our CNE-FHP-828 SPS sintering furnace (also called field assisted sintering technology furnace) was used. The vacuum degree during the experiment was 1E-1Pa, and the mechanical pressure on the sample was 50 MPa. The specific sintering process is shown in the figure below.

The CNE-FHP series SPS sintering furnace can effectively ensure the control accuracy of temperature and pressure during the experiment. As can be seen from the figure, the sintering time of a single sample is less than 1 hour. This reflects the high efficiency of the SPS sintering furnace (also called field assisted sintering technology furnace) in the material preparation test process.

The author thus obtained a series of samples with different compositions and different sintering temperatures. Then a systematic microstructure and mechanical properties analysis was conducted.

Experimental Results

The experimental results show that this process can obtain a high entropy alloy with a uniform distribution of the tungsten carbide reinforcement phase. The interface reaction process between the reinforcement phase and the parent phase is explained. The addition of tungsten carbide significantly improves the hardness and yield strength of the high entropy alloy.

This work is another example of the application of SPS sintering furnaces (also called field assisted sintering technology furnaces) in the research and development of composite materials.