As an outstanding dielectric ceramic, barium titanate has a moderate Curie temperature, high dielectric constant, and low manufacturing cost. Therefore, it is widely used in capacitors, ferroelectric memories, and other devices. However, it has poor stability at high temperatures, and its energy storage density and efficiency are relatively low, and there is still a lot of room for optimization.

Recently, Professor Meng Bin of Kunming University of Science and Technology and his collaborators proposed to design the composition of barium titanate-based dielectric ceramics by drawing on the research ideas of high-entropy ceramics. Using the direct current sintering (DCS) furnace to prepare the samples. The microstructure, dielectric properties, and energy storage properties of barium titanate-based high-entropy dielectric ceramics with different formulations were systematically studied. The relevant results were published in “Ceramics International”.

Experience Process and Result

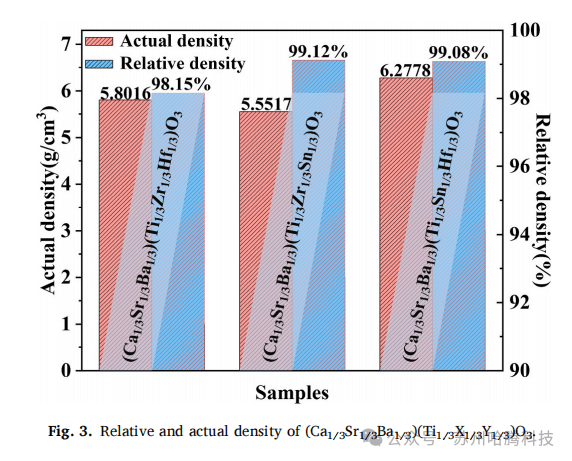

The chemical formula of the barium titanate-based high-entropy dielectric ceramic designed in the article can be expressed as follows (Ca1/3Sr1/3Ba1/3)(Ti1/3X1/3Y1/3)O3. X and Y can be Zr, Hf, or Sn. Thus, it obtained three systems, namely (Ca1/3Sr1/3Ba1/3)(Ti1/3Zr1/3Hf1/3)O3, (Ca1/3Sr1/3Ba1/3)(Ti1/3Zr1/3Sn1/3)O3 and (Ca1/3Sr1/3Ba1/3)(Ti1/3Sn1/3Hf1/3)O3.

The oxides or carbonates of the corresponding elements were prepared according to the designed composition. The raw material powder was prepared by calcination after mixed ball milling and then loaded into a graphite mold with an inner diameter of 20mm. Sintering was carried out using our CNE-FHP-808 Direct current sintering (DCS) furnace. The specific process is: sintering temperature is 1300℃, pressure is 50MPa, and holding time is 5min. A series of samples were obtained, and then their microstructure and dielectric properties were analyzed.

The density of the samples was measured using the Archimedean method and compared with the theoretical density. Figure 3 shows that direct current sintering (DCS) can obtain very high-density samples. The density of the three composition samples reached 98.15%, 99.12%, and 99.08%, respectively.

Direct current sintering (DCS) can inhibit grain growth due to its fast heating rate and short holding time, and the final sample has a small grain size. The average grain size of the three samples is 160nm, 564nm, and 727nm, all at the submicron level. The elements in the samples are evenly distributed without obvious segregation.

The energy storage performance of the three high entropy dielectric ceramics is better than that of pure barium titanate ceramics, and the first two components show higher temperature stability. Overall, this composition design is expected to obtain dielectric ceramic products with better performance.