SPS sintering WC reinforced high entropy alloy

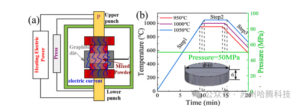

SPS sintering process can obtain a high entropy alloy with uniform distribution of tungsten carbide reinforcement phase.

Home » TECHNICAL INFORMATION » Page 4

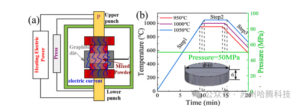

FAST (Field-assisted Sintering Technology)/ DCS (Direct Current Sintering) is an advanced powder metallurgy technology that integrates plasma activation, pressurization, heating and sintering of alloy powders. Under the combined action of current and pressure, materials can be synthesized in only one step. With its rapid heating and cooling rates, high sintering efficiency and good connection effect, it has attracted widespread attention and heated discussions among researchers. With the continuous deepening of research, this technology has been widely used in the preparation of various materials, such as metals, ceramics, and composite materials. Including materials that are not easy to sinter, novel carbon-containing materials, most nanocrystalline metal functional gradient materials and materials with complex shapes.

SPS sintering process can obtain a high entropy alloy with uniform distribution of tungsten carbide reinforcement phase.

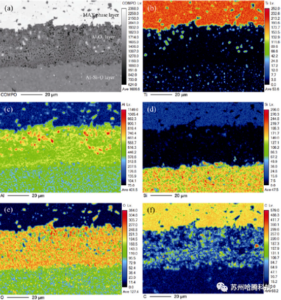

Field-assisted sintering experiment used in this work was completed on the CNE-FHP-828 field-assisted sintering technology furnace produced by our company.

This article demonstrates the excellent effect of the field-assisted sintering technology from the perspective of isotope analysis, which is good proof of the uniformity of the sintered samples.

Use the FAST (Field-assisted Sintering Technology) to prepare a dense composite blank. Finally, make it into a rod by hot extrusion. This achieved the optimization of the comprehensive performance of the composite material.

The team of Professor Yang Zirun of Yancheng Institute of Technology using field-assisted sintering technology preparation MoAlB material.

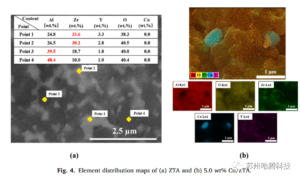

Field-assisted sintering technology preparation ZTA ceramics shows that 5% copper-doped ZTA ceramics have a lower friction coefficient.

SmCo7 alloys have a low coercive force temp coefficient. It is widely considered to be a high-temp permanent magnet alloy.

Compounded with Al2024, a zero-expansion aluminum-based composite material was prepared by field assisted sintering technique.