- Rated Power: 640 kW

- Heating Current: 60000A

- Sintering Temperature: ≤2400℃

- Pressure Range: 100-5000 kN

- Sintered Sample Size: Diameter φ80-φ400mm, Height 1-15mm

- Graphite Punch Size: φ500mm

- Head Stroke: 310mm

- External Dimensions (L * W * H): 4500*3300*4800mm

- Occupied Area:

- Weight: 10T

DESCRIPTION

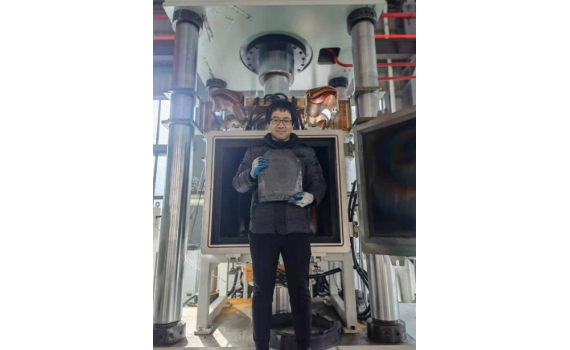

Direct Current Sintering (DCS) Furnace, also called Spark Plasma Sintering (SPS) furnace, Field-assisted Sintering Technology (FAST) furnace.

CNE-FHP-888 is used in industrial production. Its processing time is incomparable to traditional methods such as hot pressing, HIP, and atmospheric pressure sintering, and it can be produced quickly and improve efficiency.

FEATURES

Easy operation through the panel, clear and intuitive menu navigation, continuous and precise monitoring of the thermal process, data management through an intuitive graphical interface, and real-time control of the FAST/ Spark Plasma Sintering (SPS) sintering furnace. Even inexperienced people can use the FAST/SPS system quickly and safely.

Short cycle time, good vacuum conditions, uniform temperature distribution and precise pressure control are essential to ensure the quality of the final product.

Meet the requirements of advanced sintering processes, with a maximum temperature of 2200°C, a heating rate of up to 1000°C/min, and a maximum axial pressure of 1000kN. (Contact us to provide your specific process requirements and get your exclusive technical solution)

Precise and controllable sintering process: All sintering parameters can be precisely controlled (sintering temperature, pressing pressure, ambient atmosphere, etc.)

Low sintering temperature and short holding time prevent the sample grains from growing in time, which is conducive to the preparation of nanocrystalline materials

STANDARD CONFIGURATION

- Working Atmosphere: Vacuum or inert gases (Argon, Nitrogen ≤1800℃)

- Temperature measurement: thermocouple for low temperature section, pyrometer for high temperature section, automatic conversion of temperature measurement and control

- Electronic displacement measurement

- Safety interlock protection, with alarm and protection functions such as over-temperature power off, water and power off, over-current, etc., and emergency switch

OPTIONAL CONFIGURATION

- Higher temperature, higher pressure, and larger electrodes can be customized

- Vacuum glove box

- High vacuum

- Wax and drip collector to protect vacuum pump

- Water chiller

- Gas purifier (purification of inert gas)

- UPS (uninterruptible power supply)

APPLICATION

- Direct Current Sintering (DCS) furnace (also called Spark Plasma Sintering (SPS) furnace, Field-assisted Sintering Technology (FAST) furnace) has been widely used in the preparation of various materials, such as metals, ceramics, and composite materials. Including materials that are not easy to sinter, novel carbon-containing materials, most nanocrystalline metal functional gradient materials and materials with complex shapes.

FAQ

There are some advantages of FAST Sintering cemented carbide compared with vacuum sintering. For more information……

There are several kinds of molds used in the SPS process, like graphite molds, cemented carbide molds, ceramic molds used in the SPS process.

PROVIDE YOUR SPECIFIC PROCESS REQUIREMENTS AND OBTAIN YOUR EXCLUSIVE TECHNICAL SOLUTIONS!

Get In Touch

We will reply to you within 24 hours and provide you with professional and high-quality services. At the same time, we will abide by the privacy protection agreement to ensure the security of your information.

sunny@cnequips.com

Phone

+86 13973358263 / 18673339889

Address

Building 5, Gate 2, No. 288 Quanyuan Road, Wujiang District, Suzhou City